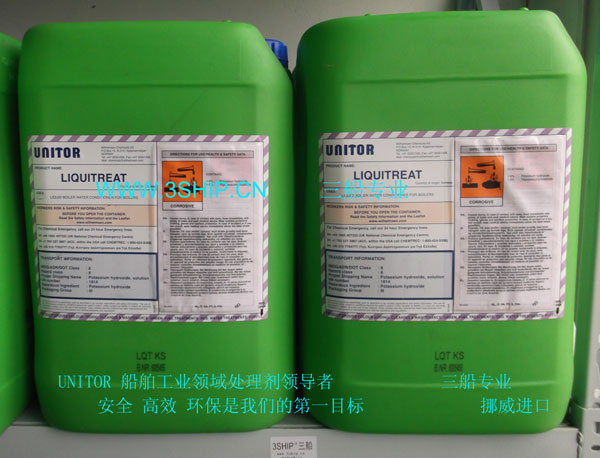

UNITOR LIQUITREAT

- IMPA 655 571273

- Time:2012-3-2

- Contact Us

UNITOR LIQUITREAT

优利多锅炉水处理剂

655 571273

Liquitreat

Liquitreat is a liquid blend of alkaline compounds, scale and corrosion inhibitors, oxygen scavengers and sludge conditioners.

Product Specification

|

Product Number |

571273 |

|

Weight |

|

|

Density |

1.1 |

|

Packing, Type |

PLASTIC |

|

Colour |

COLOURLESS |

|

Appearance |

LIQUID |

Directions for use

The main attributes of Liquitreat fall into the following categories:

· Control of alkalinity: The correct level of alkalinity ensures that optimum conditions exist for:

Precipitation of hardness salts in conjunction with phosphate.

· Neutralisation of acid conditions. Avoidance of caustic corrosion. Control of magnesium and calcium salts.

· Control of hardness: Liquitreat provides a phosphate reserve to effectively react with and precipitate the hardness salts introduced with the feedwater.

· Conditioning of sludge: Boiler sludge can only be removed by blowdown if it is free flowing. Liquitreat will ensure this by preventing the sludge from adhering to metal surfaces. The resulting sludge is composed of small particles flowing towards the bottom of the boiler.

· Control of oxygen: Oxygen scavenging becomes more important with the increase in boiler pressure. The oxygen scavenger will effectively react with dissolved oxygen even at lower temperatures.

Recommended control limits are:

P-Alkalinity: 100-300 ppm CaCO3, Chlorides: 200 ppm Cl max, Condensate pH 8.3-9.0.

Dosing method

Liquitreat is best fed into the boiler feed line with a Unitor boiler water dosing unit. Alternatively Liquitreat can be dosed by means of by-pass pot feeder. The amount required for dosage can be obtained from the dosage chart. Consult your Unitor representative for specific dosing instructions.

Ordering information

Supplied with

Dosage and control

Wilhelmsen Ships Service strongly recommends the use of Condensate Control in conjunction with Liquitreat. Condensate Control is a volatile amine that neutralizes carbonic acid in the condensate return. For optimum protection against oxygen corrosion, we recommend to maintain a minimum temperature of

|

P-Alkalinity* |

0 |

50 |

100 |

150 |

200 |

250 |

300 |

350 + |

|

Dose/ton** |

2.4 |

1.8 |

1.2 |

0.6 |

0 |

0 |

0 |

Blow Down |

* As ppm CaCO3

** ltr Liqutreat per ton boiler volume to achieve 200 ppm P-Alkalinity

Minimum dosage to reach 100 ppm P-Alkalinity for untreated water is 1.2 ltr/ton boiler water volume

Sampling and testing

A representative sample of boiler water should be drawn for analysis daily. The sample should always be taken from the same point after blowdown, cooled and tested immediately. Follow the Spectrapak Test Kit instructions and log the results. It is important that regular testing is carried out to ensure that treatment levels are correct.

Features

· Liquid conditioning treatment for simplified dosing and handling.

· Suitable for use with auxiliary boilers; waste heat units.

· Smoke or water tube boilers; up to 30 bar pressure.

· Boiler kept at peak level efficiency.

· Heating surfaces are maintained at optimum thermal conditions.

· Dispersant action suspends sludge and sediment particles for efficient blowdown.

· Oxygen scavenging for optimum protection.

· Approved by the Norwegian National Institute of the Public Health for the use in system where steam is used for drinking water production.

Documentation and literature Customer benefits

MSDS Liquitreat