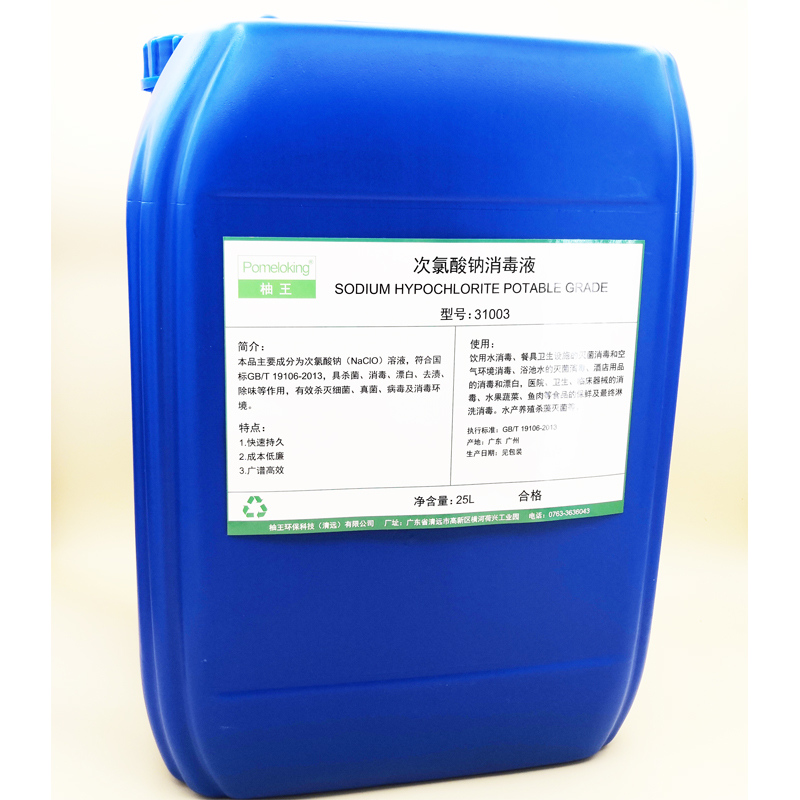

POMELOKING SODIUM HYPOCHLORITE POTABLE GRADE 25L

- IMPA 31003

- Time:2013-8-5

- Contact Us

POMELOKING SODIUM HYPOCHLORITE POTABLE GRADE 25L Overview: Grapefruit King sodium hypochlorite disinfectant (NaClO commonly known as bleach ) quality meet the national standard GB19016

Sodium hypochlorite disinfectant widely used : Sodium hypochlorite solution (NaC1O) is widely used in drinking water, hospital sewage , urban sewage, industrial wastewater treatment, industrial water recycling, chemical environmental wastewater , aquaculture, textile bleaching , pulp production, poultry slaughter , indoor air , beer manufacturing, food processing , sterilization pool water circulation , appliances , and many other areas of washing , disinfection , algae, mud stripping , bleaching , bleaching, deodorizing , oxidation, corrosion, preservation, anti- mildew , broken cyanide , phenol broken . The use of sodium hypochlorite disinfectant sterilization has the following advantages : A, rapid and sustained B, safe and nontoxic C, broad spectrum D, low-cost E, PH value is not affected Sodium hypochlorite sterilization performance: Sodium hypochlorite solution can kill all microorganisms, including bacteria, cells spores, fungi , mycobacteria and hepatitis viruses , germs and other infectious diseases . Its bactericidal mechanism of microorganisms are: sodium hypochlorite has a strong adsorption of the cell wall penetration , which can effectively make the cells containing thiol oxidation enzymes , rapid microbial protein synthesis inhibition to destroy microorganisms. This product is the most used and inexpensive domestic enterprises , the best disinfectant products. Sodium hypochlorite disinfectant range of applications : 1 , living, drinking , water disinfection various occasions ; 2 , restaurant , hotel , home, tableware sterilization environmental sanitation and air disinfection ; 3 , food and beverage plants, industrial fermentation equipment , pipes, containers final sterilization ; 4 , dairies , slaughterhouses pipeline , sterilization processing facilities and the environment ; 5 , sterilization disinfection of hospital sewage treatment ; 6 , sterilization pool, industrial circulating water , bath water disinfection ; 7 , hospitals , public health, clinical instrument disinfection , sterilization, deodorant mildew treatment ; 8 , family, hotels, restaurants, fruits and vegetables , fish and other food preservation and final rinse disinfection ; 9, the configuration of various oral disinfectant, deodorant and wound cleaning fluid , etc. ; 10 , wastewater reuse sterilization and deodorization ; 11 , with a variety of food flour bleaching agent ; 12 , paper, printing and dyeing industry, bleaching agents ; 13 , electroplating wastewater containing cyanide cyanide -breaking treatment, bleaching treatment, industrial cooling water algae sterilization dyeing wastewater treatment ; 14 , is used to kill algae aquaculture sterilization , reduce harmful toxins in water quality, improve the farming environment ; 15 , plants and flowers used to kill mold growing industry , in addition to pests, improve the soil 's pH ingredients conducive to plant growth ; 16 , animals, pet sterilization deodorant place to prevent the epidemic ;

The main purposes: as a bleaching agent and sanitizers , such as bleached cotton fabrics , chemical fiber, paper pulp , oil and starch ; for azo dyes , anthraquinone production plant and electroplating wastewater treatment plant ; using sea water for industrial cooling when water treatment inhibited by sodium hypochlorite sea creature dwelling in the pipe wall attached ; used for food packaging and tableware disinfection and corrosion inhibitors ; used as vegetables, fruits , farm , barn and other disinfectant , deodorant, in addition to using as hydrazine sulfate , hydrazine hydrate, chloropicrin , dual chloramines and other production materials.

Sodium hypochlorite solution is a strong oxidant , has a very pungent odor, instability, caused by prolonged storage easy oxidative decomposition becomes weak, Gu usually stored for 1 year is appropriate.

Risk category: corrosive substances Pathways: inhalation, ingestion , percutaneous absorption Health hazards: frequent hand contact with the product of the workers , palms sweating, nail thinning , hair loss . This product has sensitization. This product may cause a release of chlorine poisoning . Environmental Hazards : no significant pollution. Explosion hazard: The product is flammable , corrosive , can cause the body burns , with sensitization. First aid measures Skin contact: Remove contaminated clothing, rinse with plenty of water . Eye contact: Did eyelid, mobile water or saline. Doctor. Inhalation : rapidly from the scene to fresh air. Keep the airway patency. If breathing is difficult , give oxygen. If not breathing , give artificial respiration immediately. Doctor. Ingestion : drink plenty of water, induce vomiting . Doctor. Fire-fighting measures Hazardous combustion products: chloride. Extinguishing Methods: mist of water, carbon dioxide, sand fire. Spill response Emergency treatment: rapid withdrawal from air leakage personnel to a safe area , and isolation and strict restrictions on access . Recommended emergency personnel wearing self-Pressurized respirators to wear anti-acid. Do not direct contact with leakage. Cut off the source of the leak as possible . A small leak : Absorb with sand , vermiculite or other inert materials. Large leak: to build a causeway or trenching asylum . Foam coverage, lower vapor disasters. Transfer pump to tankers or exclusive collector, recycling or shipped to the waste disposal sites. Handling and storage Handling Precautions: closed operation, full ventilation. The operator must go through specialized training , strict adherence to rules . Proposed operators wear directly respirators ( half-mask ) , wearing chemical protective safety glasses , wearing overalls corrosion , wear rubber gloves. Prevent vapor leakage into the workplace air. Avoid contact with alkalis . Handling of light when light unloading , packaging and containers to prevent damage . Equipped with spill response equipment . Empty containers may be harmful residues . Storage: Store in a cool , ventilated warehouse. Keep away from fire and heat. Storage temperature should not exceed Exposure controls / personal protection Occupational Exposure Limits Chinese MAC (mg/m3): not established The former Soviet Union MAC (mg/m3): not established TLVTN: not established TLVWN: not established Monitoring Methods: Engineering controls : closed production process , full ventilation . Provide safety shower and eyewash equipment. Respiratory protection : high concentration environment, should be worn directly respirators ( half-mask ) . Eye protection : Wear protective chemical safety glasses. Physical protection: wear overalls corrosion . Hand Protection: Wear rubber gloves. Other protection: work site prohibit smoking, eating and drinking. After work , take a shower . Attention to personal hygiene.

Name: grapefruit King sodium hypochlorite solution ( 10-15 % ) Appearance: pale yellow solution Packing : Production date : See package

Product Standard: Item Index Chlorine (CL meter ) ≥ 10.0 11 The free base ( NaOH) , 0.1 to 1.0 Iron (Fe ), ≤ 0.005 Heavy metals ( as Pb ) ≤ 0.001 Arsenic (As ), ≤ 0.0001

Processing and distribution capacity Factories located in the southwest by the new Town Development Zone , covers an area of 20,000 square meters . With the most advanced production equipment and facilities bleach , have mature production technology innovation , the average daily production capacity of 600 tons , has annual sales of 100,000 tons , the products are sold to domestic and Hong Kong and Macao regions. Factory equipped with multiple cars tankers, can achieve large quantities and distribution services to facilitate customers ; demand for small quantities , dilute with scores provide equipment :

See more about chemical safety instructions MSDS