COMPOSITE HOSE PRODUCT CHARACTERISTIC

- IMPA 35

- Time:2012-11-7

- Contact Us

复合软管产品特性说明

COMPOSITE HOSE PRODUCT CHARACTERISTIC

Product description

The company customized composite hose specifications from 1 inches to 12 inches, working pressure 6BAR to 30BAR. Working temperature: -200℃ to 250℃. Using a variety of polymer sealing barrier material, can be in extremely harsh conditions hazardous material transportation.

Products through the CCS, DNV, BV, NK, CE certification.

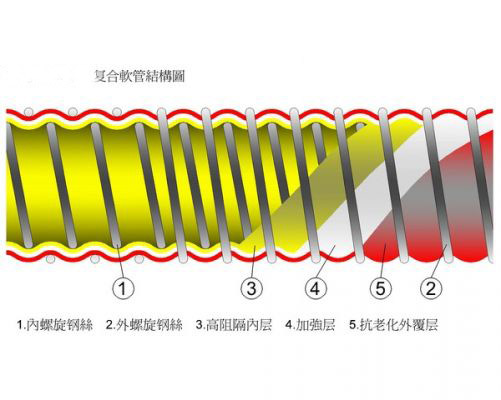

1 screw steel wire:

According to the hose conveying medium characteristics of different material: stainless steel wire, galvanized wire, aluminum alloy wire, or polypropylene ( PP ), Teflon coated wire coated steel wire.

The 2 outer spiral steel wire:

The basic choice of hot galvanized steel wire or stainless steel wire.

3 high barrier lining layer:

The hose provides resistance to chemical erosion and chemical liquid barrier, the hose quality plays a key role, usually composite hose according to convey different media characteristics and the choice of polypropylene, Teflon, or PTFE crosslinked polyethylene etc. ... Functional materials, our company with the international famous suppliers to develop a variety of functional materials, through proprietary technology compound hose has excellent fatigue resistance, resistance to chemical corrosion and close to zero chemical liquid penetration rate and safety performance.

The 4 reinforcing layer:

Composite hose body is composed of layers of functional polymer membrane and synthetic fiber fabric reinforced layer. The inner and outer two layers spiral wound with wire fixation.

5 anti aging coating layer:

Composite hose layer is the waterproof and anti wear PVC weaving composition selection of materials, for the majority of corrosive chemical special chemicals and hydrocarbons are very good resistance, suitable temperature from 30 degrees to 115 degrees c.. Because of the composite hose CompositeHose composite hose with a lightweight, safe, strong, corrosion-resistant, high temperature and other characteristics, it can replace the traditional rubber pipe and metal hose.

Tube characteristic

A, light weight.

Composite hose than the same specifications of rubber hose 40% lighter than metal hose light 30%, greatly reduces the labor intensity of an operator, convenient operation, effectively improves working efficiency.

B, bending strength, bending easily, without the limitation of working space.

Composite hose can be in a very small radius of gyration work, at the bending part, pipe always maintain a round shape, not folding, inner shedding and tube body fracture phenomenon.

C, positive, negative pressure performance.

Composite hose maximum working pressure up to 30 M Pa, negative pressure can reach 0.1 M

D, good temperature resistance.

Composite hose working environment temperature - 30℃~ + 115 ℃, not because of the climate or the use of temperature changes and the emergence of the tube body hardening or softening phenomenon.

E, has good oil resistance, chemical corrosion resistance.

Oil resistant composite hose has dozens of layers within the sealing layer, selection of high-tech materials and reliable anti permeation barrier properties, very low fuel absorption swelling properties. Suitable for conveying the aromatic hydrocarbon content of 100% petroleum products. Oil resistant performance is better than that of NBR rubber and can be used in a higher temperature range. Conventional oil pipe lining mainly using a modified polypropylene as inner layer seal, special requirements can be made of nylon polyester and other dozens of materials.

The modified polypropylene excellent chemical stability, acid, alkali, salt for most, oxidants are significant inert. For example, in the 102℃concentrated phosphoric acid, hydrochloric acid, sulfuric acid and other 40% salt solution is stable, with only a few strong oxidizing agents such as fuming sulfuric acid and so on to make the change. POLYPROPYLENE is a non-polar compounds, in polar solvents such as alcohols, very stable, phenols, aldehydes, ketones and carboxylic acids are most does not make the swelling, but in part of nonpolar organic solvent to dissolve or swell, POLYPROPYLENE environmental stress cracking resistance performance is better than that of PE, in many solvents, cleaning detergent no stress cracking, POLYPROPYLENE has outstanding resistance to flexural fatigue performance, it made the hinge through 70000000 folding bending damage. POLYPROPYLENE creep resistance.

F, has good electrostatic derived function

When the oil transporting inflammable medium, because of pressure, velocity, friction factor and so on, will produce a certain static, if not timely export, consequences would be unbearable to contemplate. Composite hose is composed of inner, outer double wire support connection, excellent conductive performance, safe use.

G, hydraulic shrinkage forming a sealing, good sealing performance.

Composite hose pipe body and the flange connecting part, has changed the traditional method, using large hydraulic equipment forming a close connection, compared with similar products, good sealing performance, beautiful appearance, and more supervision solid and durable, not due to rapid increase of pressure and joint off phenomenon.

PTFE ( Tefulong ) composite hose

Hose lining the use of fluorine polymer PTFE, PTFE each hydrogen atom with polyethylene for fluorine atoms replaced by chemical structure, molecular weight of up to 200-1020 million polymeric long chain structure, the Hara Ko has a very strong chemical bonding force has excellent chemical properties. In addition to the fluorine gas, chlorine and alkali metal fluoride three, ability of various other chemicals, free from all kinds of acid and alkali, oxidant and organic solvents chemical resistant performance, PTFE ( Tefulong ) composite hose is designed in order to transport ( transport ) to send a strong corrosive chemical solvent and design, the hose can the use of the suction or discharge of the different operating mode. PTFE ( Tefulong ) composite hose using the PTFE film and the 316 stainless steel produced by. It can not only make the tube itself has a maximum resistance strength of corrosive chemical solvent also allows the hose in the high temperature working environment can be used. So PTFE ( Tefulong ) composite hose can be transported with high corrosive chemicals and fluid. Or conveying complex drug compounds etc ...

PTFE ( Tefulong ) composite hose for extremely powerful and flexible characteristics, provides the user can use the simple use and used in all areas, from the ground to the sea or space transportation.

The following are the conditions in various experimental conditions:

Chemical liquid absorption curve

Experimental conditions: 95 ℃for 51 days

Availability of standard A following A-B B-C X Y

Availability of all products except chloroform chloroform without

Based on the practical application of the chemical liquid

In chloroform and chlorinated solution slightly affected, but according to use conditions selection of foot can be used, in addition to the above several chemical materials can be used.

Immersion in various types of chemical liquid weight changes

Chemical liquid salt

Acid 35% sulfur

98% nitric acid

Acid 60% salt

Acid chrome 51%

Acid 51% B

Acid 51% acetic anhydride.

Generality

Su

51% ammonia

28% chlorine water

To change

Sodium 30% heavy

Chromium

Acid

Salt

A

10% methanol ethanol propylene

Alcohol four

Chlorine

To change

Carbon chloride

Imitation three

Chlorine

B

Allyl methyl

Benzene two

A

Benzene is

Has

An armor

Base

B

Alkyl

Base

Aniline butyl ketone

Acid ether two

Dumb

Alkane two

B

Base

Amine formaldehyde phenol

Weight change % 0 0 0 0 0 0 0.1 0 0 0 0 0 0 +0.2 +0.3 +0.9 +0.8 +0.3 +0.4 +0.3 +0.6 +0.2 0 +0.2 +0.1 +0.4 +0.4 0 0

The soaking condition:

80-90 ℃chemical liquid ( 336h, using hydrochloric acid must be kept at room temperature. )

Experimental data:

The above experiments is the hose inner sampling in the laboratory under the particular conditions of detection results, for reference only. The hoses in actual use by human and complex environmental effects may be associated with experimental somewhat difference, hose selection should also be considered when the metal parts of the corrosion resistance, the specific environment when the hose and please contact our engineers

Safety performance:

PTFE use of safety precautions:

When the fluorocarbon polymer PTFE temperature exceeds the normal temperature ( 205 ℃ -260 ℃) will produce HF, COF2 toxic gas, in the use of hose or processing waste must comply with local laws and regulations in accordance with the relevant specification by professional staff or department for processing

Range of application:

1 petroleum industry - transport diesel, gasoline, kerosene, lubricants, oil, natural gas and other petroleum products chemical industry; 2 - Transport benzene, alcohols, vinyl, acid, alkali and other chemical mediators such as liquid or emulsion;

3 Ship Industry - liquid medium loading and unloading operations and offshore feeder, sewage discharge and other;

4 - dock warehousing industry, liquid loading and unloading operation and switching station soft links;

5 paint industry, ink, pigment solvent with corrosive liquid medium conveyance;

The 6 truck - loading and unloading of various liquid medium;

7 sea mining equipment of soft connection and a variety of liquid loading and unloading operations.